The history of the paper, a presentation for a lesson on the world around us (senior group) on the topic. Conversation for children of the senior preparatory group with a presentation: What is paper? What were books and paper made of in ancient times?

To use presentation previews, create a Google account and log in to it: https://accounts.google.com

Slide captions:

History of paper

CAVE DRAWINGS

CLAY TABLETS They were inconvenient to carry and store, they were heavy, fragile, and easily broken.

EGYPTIAN PAPYRUS

PARCHMENT FROM LEATHER Parchment was very heavy and expensive. It took a herd of calves to make one book.

The Chinese kept the secret of making paper secret for many centuries. After 800 years, paper was made all over the world. Wood is used as a raw material.

Paper is produced in pulp and paper mills

First you need to prepare wood, cut down a lot of trees.

LOGS ARE BROUGHT TO THE PLANT

Chips are obtained from logs - small chips, then they are COOLED IN A SPECIAL SOLUTION

The result is a slurry, which is squeezed out and fed to a paper-making machine. The pulp is distributed, dried, ironed.

The finished paper is wound onto huge rollers.

Huge rolls of paper are being wound up.

Then it is cut into sheets and folded into bundles. The paper is READY!!!

The lumberjacks cut down the tree, divided it into parts on a machine, chopped the logs into chips, and boiled them in a solution for a long time. And then all the liquid is squeezed out, ironed with a roller, dried, ironed. This is how a blank sheet of paper comes out for a magazine, book and notebook.

In our lives, paper is found everywhere and is used everywhere.

WHAT'S EXTRA HERE?

Trees are an important part of nature. They decorate our planet!

The forest is home to many animals and birds.

Trees clean our air!

We must use paper sparingly to save trees. Used paper (called waste paper) can be made into paper again. This way we will save the lives of many trees in our forests.

On the topic: methodological developments, presentations and notes

Notes on the surrounding world in the senior group "History of the emergence of Moscow."

To consolidate children's knowledge about the history of their hometown. Introduce you to the founder of your hometown....

But how does a huge tree turn into a beautiful notebook, book or stack of white sheets? Let's figure this out together.

How paper is made

Paper is produced in paper mills. Logs are brought from the forest to the factory. The most commonly used are pine, spruce, birch, as well as eucalyptus, poplar, and chestnut.

On a special platform, the bark is stripped from the logs and crushed into chips. The fragments are then transported on a conveyor belt to a pulp mill, where they are boiled in a special solution. The result is cellulose, the main raw material for paper production.

Interesting! One tree produces 2857 notebooks of 12 pages. It takes 60 years to grow a mature tree. That is why it is important to use textbooks and notebooks carefully, because all of these are cut down trees.

The most economical way to obtain wood pulp is mechanical. The wood processing plant grinds the timber into crumbs and mixes it with water. This is how low-quality paper is made - for example, for newspapers.

But for the production of high-quality paper - for magazines, books and brochures - they use chemical method. Using sieves, the fragments are sorted by size. Then the crushed wood with the addition of acid is boiled in special machines.

The cellulose then passes through filters and is washed to remove impurities. At this stage, waste paper can be added to the raw material, but it must first be cleared of ink.

The next step is adding adhesives and resins. The first ones repel moisture, the second ones prevent the spreading of ink, which is often water-based. It is thanks to these processes that what is written in your notebook does not smudge and is easy to read. Printing paper does not require such sizing, because printing inks are not water-based.

But that's not all. Then pigments and dyes are added to the paper raw material. For example, the white color of paper is obtained by adding kaolin.

After this, the paper pulp enters the paper machine onto a conveyor belt. Here, using tiny porous holes and pressing with various rollers, moisture is removed from the paper and a continuous roll of tape is formed.

At the “wet pressing” stage, the paper is finally dried, dehydrated and compacted. The result is a smooth white tape wound onto a huge roll. The paper is ready! Can be sent to book factories. There, the paper web is cut to create books and notebooks.

You can learn all the intricacies of paper production from the video.

How are books made?

So, after the author writes the text and the editor of the publishing house approves it, the proofreading process. The work is checked for errors. Ideally, the proofreading team reads the text several times. After this, illustrations are selected for the book.

Then it begins layout. Using a special computer program, the layout designer selects the book format, margin size, types and sizes of fonts, and determines the location of illustrations and text.

The next stage is called color separation. Did you know that to print a fashion magazine cover you only need four colors: blue, pink, yellow and black? Therefore, now the designer must divide all illustrations into four components.

The most important stage is book printing. Using rollers on a printing machine, the ink is rolled out to a thin layer, fed onto a printing plate, which rotates and applies the image to a continuous roll of paper.

Interesting! Printing house workers can print several thousand sheets in one shift.

It is difficult to imagine any book without a cover. Therefore, the next stage is creating the “face” of the future book. If the cover is ready, it is placed on the book block and trimmed. If a hard cover is being made, the book is trimmed before the cover is glued on.

That's all - the book is ready to delight the eyes of admiring buyers, all that remains is to pack it. You can see with your own eyes how books are made in the next video.

What were books and paper made of in ancient times?

Once upon a time there were no books in the form in which you see them in store windows or in libraries today. And all because people did not know how to make them. Instead of paper, humanity used cave walls, stones, dishes, tree bark…

Years passed and people came up with the idea of making records on wet clay. However, such books were too heavy, inconvenient and short-lived.

After some time, the heavy clay cloth was replaced calf or goat books skins are light and practical. Since the first such book was created in the ancient city of Pergamum, the “paper” made from animal skin was called parchment.

However, such material was too expensive, because to create one book, it was necessary to slaughter many calves. So people kept looking for cheaper and easier ways to create books. And they succeeded.

Along the rivers of Africa there grows a tall marsh plant - papyrus. People did not immediately realize its amazing properties. At first, the plant was used in the construction of houses. But one day a man was repairing his house. I cut the stem, took out the fibrous center and put it in the sun. Imagine the man’s surprise when he noticed that the fibers had turned into dry, narrow ribbons. And when he saw that papyrus also absorbs paint well, he realized: you can write on papyrus! This is how books made from papyrus appeared.

But who and when invented paper as we see it now? Researchers assure: the palm belongs to the Chinese. They came up with the idea of producing paper from young bamboo shoots.

Interesting! ...And before that time, the Chinese wrote on silk or bamboo tablets. The Chinese jealously guarded the mystery of silk production. However, silk was very expensive, which means-inaccessible to the majority of the population, and bamboo- too heavy. Only 30 hieroglyphs were placed on one board. Information has been preserved: in order to transport some works, the Chinese needed a whole cart.

Chinese chronicles report that invented paper in 105 AD. e. Tsai Lun.

“Everyone highly appreciates the work of Tsai Lung: he invented paper, and his glory lives on to this day...”- says the chronicle.

The 4th century was a turning point in the history of paper making. After the technology of its production was improved, paper replaced bamboo planks forever. New experiments have proven that paper can be produced from cheap plant materials: tree bark, reed, bamboo. The Chinese were especially happy about the latter: bamboo is a dime a dozen in their country.

No matter how hard the Chinese tried to keep the secret of paper production, they failed. In 751, during the fight against the Arabs, several Chinese craftsmen were captured. From them Arabs They learned the secret of creating a mysterious product and for five centuries they profitably sold it to Europe.

Oddly enough, but Europeans were the last of the civilized peoples to learn how to make paper - somewhere in the 11th-12th centuries. The Spaniards were the first to borrow paper production technology, then the Italians, Germans, English... It is interesting that for a long time paper was made not only from soaked tree fibers, but also from rags and other rags.

The first industrial paper production machine was invented in France in 1798.

On the territoryand Ukrainian lands Paper production began in the 13th century in Galich. However, documented information about Ukrainian paper “factories” has been preserved since the 16th century. Researchers of the history of the Ukrainian paper industry have found materials about 200 “factories” that operated on the territory of Ukraine from the 16th to the beginning of the 20th century, which indicates the high cultural level of the then population.

Radomysl Castle in Radomysl, ZhitomirShchyna is the first paper mill in Central Ukraine, built in 1612.

Now paper surrounds us everywhere, conquering more and more new areas of application every year. That is why it is so important to remember that it is made from trees - forest resources that are catastrophically decreasing every year on the planet.

Treat books with care, use paper sparingly, recycle waste paper, plant trees - the least that everyone can do to preserve forests. And one inventive boy, in order to preserve forest plantations, even refused to write an essay. =)

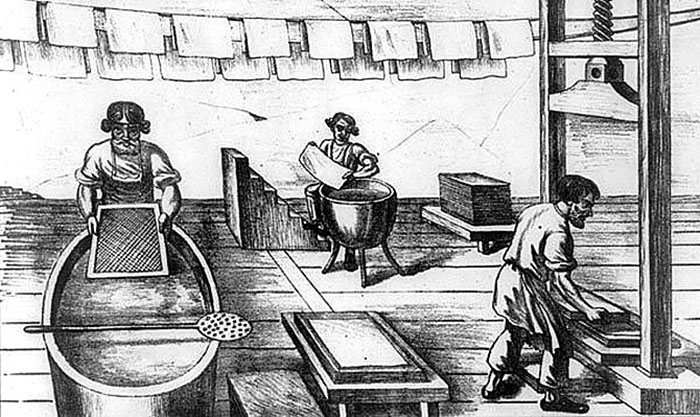

The Chinese ground tree bark, wood chips, and rags in water for a long time until they got a porridge without lumps, then they poured this mixture onto trays, at the bottom of which there were long narrow strips of bamboo. When the water drained, the soft sheets were laid to dry on a flat surface. Bamboo and old rags were used for this purpose. Later, someone figured out how to improve the quality of paper by adding starch to it.

The paper was made by hand, using the most primitive techniques. We received no more than 100–120 kilograms per day. With the development of printing, more and more paper was needed. There was not enough rags, which thousands of people collected. And then we decided to try wood. The experiment was a success - the wood was split into individual fibers and turned into paper pulp. Since then, paper has been produced from wood.

One day the Arabs defeated the Chinese army and captured prisoners. They extorted from the captured Chinese how to make paper. One day the Arabs defeated the Chinese army and captured prisoners. They extorted from the captured Chinese how to make paper. Trade caravans from distant countries came to China to buy goods and bought paper as their greatest value. The Chinese strictly kept their secret and for 800 years no one was able to find it out.

Nowadays paper is made in much the same way, only machines do it all. Paper machines produce paper strips several meters wide at a speed of meters per minute.

Nowadays paper is made in much the same way, only machines do it all. Paper machines produce paper strips several meters wide at a speed of meters per minute.

Paper in our lives. Paper properties.

CONCLUSION: My assumption was wrong, paper is not made from dry tree leaves, but from wood and other materials; During the work, I made paper at home, researched the properties of various types of paper; mastered new ways of obtaining information.

Conversation for children 5-7 years old with presentation: “What is paper?”Dvoretskaya Tatyana Nikolaevna, GBOU School No. 1499 DO No. 7 Educator Description:

The conversation is intended for older preschool children, preschool teachers, and parents. Purpose of work:

The conversation will introduce children to the stages of paper production. Target:

developing a caring attitude towards paper in preschool children.

Tasks:

1. captivate children with an interesting story about paper production;

2. introduce children to the stages of paper production;

3. instill in children of senior preschool age a careful attitude towards paper;

4. to develop children’s environmental culture and skills for rational use of natural resources; Epigraph:

Children are young creators, they draw all kinds of pictures every day. Sometimes the drawing doesn’t work out and the children throw it in the trash. Kindergarten teachers need to teach children to be careful with paper.

Conversation: What is paper? Presenter:

Guys, look what I'm holding in my hands? (Sheet of paper) Yes, this is an ordinary sheet of paper that you like to draw on.

Slide No. 1

Do you know that before there was no paper? What happened instead? To find out the answer to this question, scientists studied ancient manuscripts and excavated ancient cities for many years.

So where did paper come from? It turns out that a long time ago people wrote on birch bark. What is birch bark? (Children's answers)

Slide No. 2 Birch bark

– the outer part of birch bark (showing birch bark).

Scientists found birch bark letters during excavations of the ancient city. These are letters and documents written on birch bark. The letters are scratched with special bone tools. But this method of writing was inconvenient, since the birch bark scrolls took up a lot of space.

Slide No. 3 Then people came up with sheets from the thin skin of young animals -.

parchment

It is a very durable material (sample showing thin leather). Previously, there were even entire parchment books. To protect them from scratches, they were bound with copper, and the book resembled a chest.

But time passed, and a new material appeared that was much thinner than parchment. In ancient China they came up with a recipe for making paper. It was easy and convenient to write on. This material was admired by all countries as a curiosity, but the wonderful method of making it was kept strictly secret.

Many years passed and residents of other countries learned how to make this miracle.

What do you think paper is made from? (Children's answers) If children find it difficult to answer, let's turn to the riddle.

Slide No. 4

Mystery: In a fur coat in the summer, and undressed in the winter. (Trees)

Tree is a perennial plant that has one solid stem (trunk), roots, branches and leaves.

Think and name the products that are made from wood? (Children's answers)

Slide No. 5

Trees are the wealth of our nature. Wood is used to make: furniture, boards, wooden houses, pencils, paper, matches and much more.

Slide No. 6

In order to learn how paper is made from wood, you need to go to a paper factory. It is there that logs cut from the forest are brought.

At the factory, the bark is stripped from the trees, crushed into chips, and the chips are sorted, special aqueous solutions are added, and sent for cooking.

Slide No. 7

There are two types of wood processing:

1. Mechanical method

The paper turns out to be fragile and is used to produce newspapers.

Slide No. 8

2. Chemical method

The wood produces paper pulp, which goes into a paper-making machine, which has many, many rollers.

Slide No. 9

Some rollers are wrung out, others are dried, and others are polished. This way, moving from roller to roller, our wood turns into high-quality white paper.

Slide No. 10

Tell me guys, why do people need paper? (Children's answers)

Leading: Many objects around us are made of paper. Look and name these items. (Children's answers)

1. School supplies: books, textbooks, notebooks, notepads, sketchbooks, colored paper;

2. Products for the apartment: newspapers, magazines, wallpaper, napkins, toilet paper;

3. Packaging products: boxes, containers, wrapping paper, etc.

All this requires a lot of paper. At the same time, forest areas are rapidly shrinking. In order not to cut down forests, people came up with the idea of handing over waste paper and making paper from it.

Slide No. 11

Waste paper– these are paper products used in everyday life (old newspaper, notebooks, magazines, boxes, etc.) This is how paper gets a second life and is called recyclables.

Slide No. 12

Let's learn to save paper!

In our kindergarten, a waste paper collection campaign was prepared and carried out. The interaction of parents, students and teachers brought benefits to the environment and joy to the participants of the action.

Slide No. 13

Together we managed to collect 350 kilograms of waste paper. It is especially pleasant to note the fact that 250 kilograms were collected by activists of our group.

Slide No. 14

October 24 is International Paper Free Day.

The motto of the day is to teach people to use paper rationally (economically).

Slide No. 15

Our achievements:

- We have learned to save paper!

- We found out how paper appeared!

- We learned to draw beautiful trees!

- We learned how to collect and hand over waste paper!

- We saved the trees from being cut down!

Slide No. 16

THANK YOU FOR YOUR ATTENTION!

Recommendations: In order to update children’s knowledge, conduct a conversation: What do trees give people?

- Trees are long-lived plants (age from 100 to 300 years)

- Trees are a “home” for animals and birds (hollows and nests)

- Trees are a “forest dining room” for birds and animals (fruits and seeds)

- Trees purify and humidify the air, creating coolness in the summer heat.

- Fruit trees - produce delicious edible fruits.

- Trees benefit us even when they are cut down.

- Sawn wood is a building material: dried trunks are used to make boards, plywood, furniture, toys, and paper.

- Trees grow slowly, so they need to be protected, protected and taken care of.

- Young trees need to be planted in the spring.

- Every second tree cut down on Earth dies to make paper.

- Every day, people throw away huge amounts of paper, polluting the environment, instead of reusing it.

Presentation on the topic: What is paper?

PROJECT HISTORY OF ORIGIN AND MANUFACTURE OF PAPER

MALKOVSKY ARTEM ALEXEEVICH

3rd "B" CLASS STUDENT

SCHOOL No. 54

SUPERVISOR:

KASYANYCHEVA ANNA ALEKSANDROVNA

SECONDARY SCHOOL TEACHER

Objective of the project1) Get acquainted with the history of the appearance of paper and its

production today.

2) Tell others about what you have learned.

- Meaning of the word paper.

- Technological process of paper production.

- Waste paper.

- Conclusion.

2. Who, where and when invented paper?

Paper. She accompanies us everywhere and everywhere. Modern man

can't imagine himself without her. We write, read, draw, cut and look at pictures... Sometimes, without thinking, we spend an infinite amount of it.

What does paper mean? Who and where invented it? What was it made of and how was it made?

before and is it being produced now? What interesting facts about paper can you find out, is there a connection between the use of paper and the state of the environment?

The purpose of my work is to establish and prove that the invention of paper

this is humanity's greatest achievement. We will prove that the use of paper has a negative impact on

state of the environment.

Invention of paperPaper was invented by the Chinese. They began to make it from soaked

plant fibers. Paper came to Europe between 1000 and 1100 years.

Gradually, paper began to be produced here too. It turned out that it can be

made not only from plants. Paper began to be made from wood, rags and even...

from old paper. It turned out that the paper could be used

Paper was invented in China by an important official at the emperor's court, Chai Long.

This discovery was important not only for China, but also for the whole world. The name of Chai Lun is rightfully included among the names of the greatest inventors in human history.

Paper making today

Paper is produced in paper mills.

The main raw materials for production

paper is wood pulp.

Cellulose is obtained from forest species:

mainly from spruce, pine and birch, but

Eucalyptus, poplar,

chestnut and other trees.

At the factory, machines strip the bark from the trees and crush them into chips.

The most economical way to obtain wood pulp is mechanical: at a wood processing plant, timber is crushed into crumbs, which are mixed with water. Paper made from such cellulose is fragile and is most often used in the production of, for example, newspapers.

Higher quality paper is made from chemically produced cellulose. This wood pulp is used to make paper for books, brochures and fashion magazines, as well as durable wrapping materials.

In this case, the chips are sorted by size on special sieves and sent for cooking. The wood is boiled in special machines to which acid is added.

Cleaned and boiled wood is filtered and washed to remove impurities.

Waste paper can be added to the processed paper pulp, but only after the ink has been removed. At this stage of production, the processed pulp, consisting of wood fibers and water, is called raw paper.

Then, a special processing machine changes the shape and structure of the paper fibers. To do this, additional substances are added to the paper raw material. For example, adhesives - their presence in writing paper repels moisture. Or resins - thanks to them, what is written on paper with water-based ink does not spread and is easily recognized by the human eye. Paper used for printing does not require the same sizing as writing paper, because printing inks are not water-based and do not bleed.

After this, the paper is dyed in a mixer, where dyes or pigments are added, for example, finely ground coating substances. Thus, kaolin additives make paper white and opaque.

The paper pulp, turned into pulp, enters the paper making machine.

First, the slurry is poured onto the mesh of the paper machine. This mesh is stretched over two shafts and rotates all the time, carrying the paper pulp forward. At the mesh section, the formation of the paper web, called sheet forming, begins. This occurs by removing water from the fibrous material. As the paper pulp moves along the conveyor belt, some of the water contained in it flows out through the mesh holes, and the paper fibers begin to intertwine with each other, forming the so-called roll tape.

The raw paper strip passes through a series of rollers. Some rollers squeeze out the water, others, heated from the inside by steam, dry it, and others polish it.

At the end of the wire section, the still wet paper web is moved to a pressing section, which is also called “wet pressing”. There, the paper web is mechanically dehydrated and further compacted.

Finally, the smooth white tape comes out of the machine and is wound into a huge roll.

Then these rolls are sent to printing houses or cut into sheets.

So, moving from machine to machine, the wood turns into white and clean paper.

Application of paper

Made from paper : newspapers, books, money, notebooks, napkins, cardboard and many other goods.

Stages of making paper from waste paper:

1. Soak old newspaper in a bowl.

2. Drain the water.

3. Using a mixer or wooden spoon, turn the soaked paper into a homogeneous mass.

4. To get colored paper, add a little paint to the mixture.

5. Transfer the mixture to another bowl and add water.

6. Place a wire mesh in a bowl on which the future paper will settle.

7. Place a piece of fabric on a smooth, flat surface. Quickly and carefully transfer the mesh with the paper pulp onto it and place it with the mass facing down.

8. Press the mesh firmly and carefully remove it. The paper pulp should remain on the fabric.

9. Cover the mixture with a second piece of cloth and press tightly.

10. Cover with plastic wrap and place a weight on top.

11. After a few hours, when the mass has already become paper, carefully remove the resulting sheets and lay them out on newspapers to dry completely.

12. Dried paper can be used.

Waste paper - waste from the production, processing and consumption of all types of paper and cardboard, suitable for further use as fibrous raw materials.

Recycling waste paper is of great importance, since its use allows saving wood raw materials.

One ton of waste paper replaces 4 cubic meters of wood (40 - 50 large fir trees and pine trees).

Waste paper– protects our forests!!!